“Glass shatters, earthenware crumbles; porcelain is otherworldly in its beauty and strength,” The White Road: Journey into an Obsession: de Waal, Edmund de Waal, British artist, potter and author.

Porcelain, that ethereal object known to some as White Gold, originated a millennium ago in China and was introduced to Europe 200 years later where it entranced the continent’s elites with its beauty and intricacy.

In the centuries since, porcelain has fascinated with the duality of its form – both delicate but durable; exquisite yet strong. From simple materials extracted from the earth, the most extraordinary objects are created. And as its manufacture evolved from small-scale craftsmanship to fully-fledged industry, so too the desire grew to perfect ever-whiter, more beautiful and translucent items – a drive that was once dubbed “porcelain sickness.”

In Egypt, Fathy Mahmoud’s Egyptian German Porcelain Company (EGPC) has been part of this obsession since 1986 when porcelain productions began, bringing together expert craftsmanship and the latest technology to produce a range of stunning products that have adorned tables across the world.

Renowned sculptor Fathy Mahmoud was the man behind the vision, a fitting founder as it takes a real artist to understand the true value of porcelain.

Founded in 1948, Fathy Mahmoud has become today a global leader, exporting its porcelain tableware to over 55 countries. One of the world’s most prominent porcelain manufacturers, we create 7 million pieces a month at a unique facility in Alexandria that brings together every stage of production under one roof.

Integrating tradition with innovation, Fathy Mahmoud is able to meet large-scale global demand while maintaining exceptional quality. With a team of over 4,000 skilled artisans and professionals, we pride ourselves on creating porcelain that merges the precision of advanced German engineering with skilled local craftsmanship.

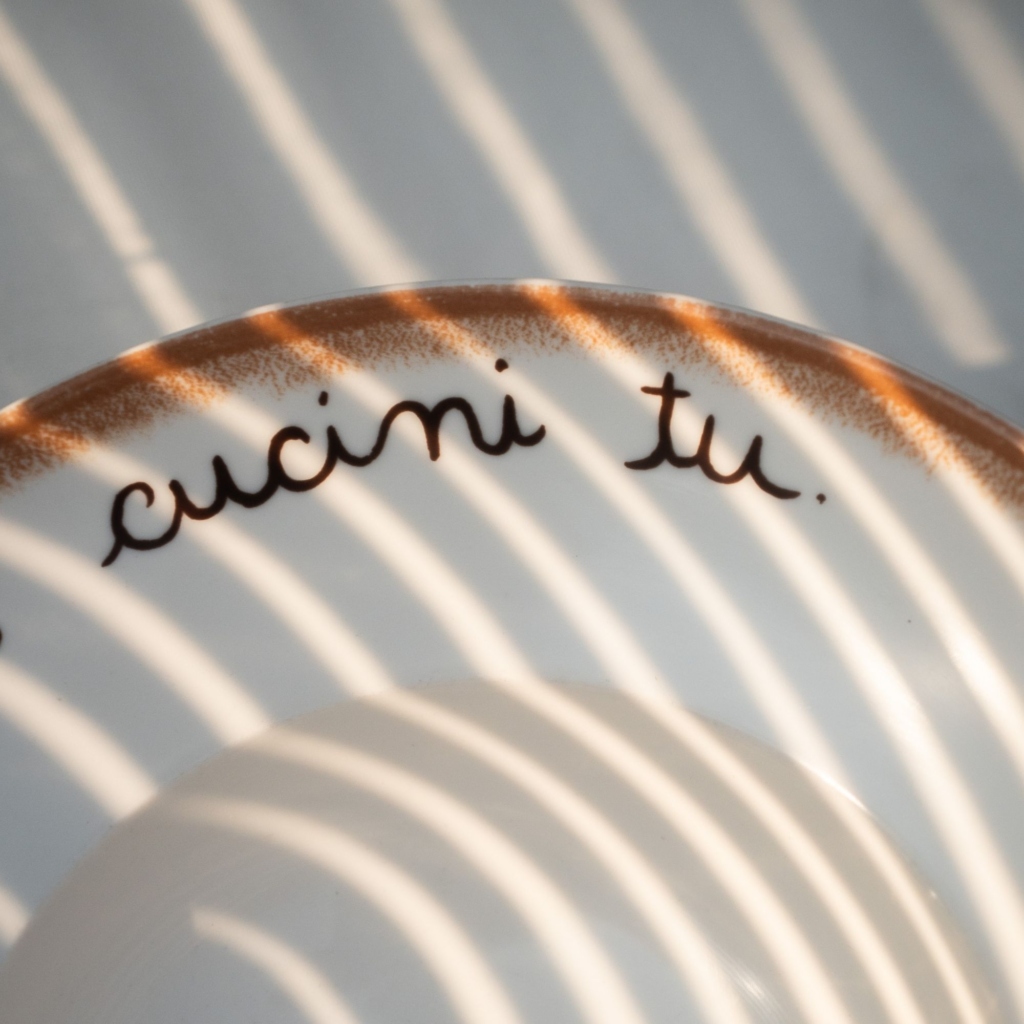

We offer more than 50 unique shapes and endless customization options for decals and glazes, meaning we can meet the diverse tastes of our global clients.

At Fathy Mahmoud, our advanced body preparation department uses a secret recipe refined over decades to deliver exceptional porcelain quality, and our in-house lab tests for whiteness, strength, porosity, and shrinkage.

Since 2007, we’ve produced our own granulate, jiggering cylinders, and casting slurry using Egyptian and international raw materials—offering unmatched flexibility and cost-efficiency.

We combine tradition and technology to craft porcelain with precision and artistry.

CNS Molding for precision: To achieve highly detailed and intricate designs, we utilize Computer Numerical Control (CNC) technology, enabling the creation of molds with exceptional surface accuracy, ideal for complex reliefs and sophisticated patterns

In-House Mold Departments: Design and machining teams ensure creativity and precision using state-of-the-art German CNC machines.

Five Specialized Forming Lines:

* Isostatic Pressing: For perfect plates and bowls using 51 heads and 93 fettling robots.

* Casting: Manual and automatic methods for complex shapes.

* Jiggering: Traditional spinning for cups and round forms.

* Pressure Cup Machines: Precision-forming for cups and detailed items.

* Pressure Casting: Ideal for artistic and intricate pieces.

At Fathy Mahmoud, we use advanced German kiln technology and a double-firing process—biscuit and glaze—at over 1320°C to produce durable, bright white porcelain with a brilliant finish.

We use both automated and manual glazing machines, along with advanced glaze-spraying robots, to ensure precise, consistent control over glaze thickness. In our colour lab, specialists craft an extensive range of glazes in endless possible colours. We offer a variety of finishes, including, reactive and solid glazes, as well as classic white and ivory. For those seeking a more artisanal touch, glazes can be applied by hand for a unique finish on each piece.

Despite advancements in the industry, handcrafting remains a key feature in porcelain production. In our handmade department, artisans use paintbrushes to create designs that can’t otherwise be achieved and work with luxurious materials including gold and platinum and precious colors sourced from Japan.

For years, EGPC imported transfer paper known as decal from Europe. Since 2011, however, our factory has proudly operated its own department, utilizing advanced German printing techniques and machinery to create a wide array of designs. These are skillfully applied to the porcelain in the decoration department and then fired, both onglaze or in-glaze.

Today our in-house decal factory has specializes in limitless designs using advanced German printing technology, including gold and platinum accents. Guided by an Italian designer and a 22-person team, we create custom logos and prints in up to 20 colors with precision using Computer-to-Screen technology. Swiss climate systems maintain ideal humidity for flawless application.

True to our pledge to be at the cutting edge of the porcelain industry, Fathy Mahmoud now offers digital printing. This efficient décor application process not only conserves materials but also accelerates production and reduces costs. We operate five specialized machines – for both flatware and vertical applications – enabling intricate effects such as engraved decorations.

Digital printing allows for multiple applications, with designs printed directly on the biscuit body creating a unique engraved pattern or on porcelain after the glost firing.

At Fathy Mahmoud, we use European-standard cardboard for our cartons and packaging, ensuring maximum protection for fragile, heavy tableware so it arrives safely every time. We also offer customized label markings on each carton for easy identification. Working with a trusted network of partners, we provide tailored packaging solutions that meet every client’s specific needs.